It is a process in which air is blown through molten pig iron to oxidize and remove unwanted impurities. Also patented by sir henry bessemer of great britain, this process produced the first inexpensive steel, which became the.

His invention of the pneumatic process of steelmaking revolutionized the industry.

Henry bessemer und william kelly. This was bessemer’s starting point. It is a process in which air is blown through molten pig iron to oxidize and remove unwanted impurities. Who brought the bessemer process to america?

11, 1888, louisville, ky.), american ironmaster who invented the pneumatic process of steelmaking, in which air is blown through molten pig iron to oxidize and remove unwanted impurities. His invention of the pneumatic process of steelmaking revolutionized the industry. An american, william kelly, initially held a patent for a system of air blowing the carbon out of pig iron, a method of steel production known as the pneumatic process.

Also realized things could be added to hot iron to make it into steel. 21, 1811, pittsburgh, pa., u.s.—died feb. He held the temperature of the melt by burning out the carbon.

Also patented by sir henry bessemer of great britain, this process produced the first inexpensive steel, which became the. Included both blowing air through and adding ingredients to molten iron. Asked sep 29, 2016 in history by janessa.

While bessemer was working on his process in england, an american, william kelly, developed a process using the same principle, which he patented in 1857. As stated earlier, bessemer had obtained patents in england and in this country previous to kelly’s application; The bessemer process was the first inexpensive industrial process for the mass production of steel from molten pig iron before the development of the open hearth furnace.the key principle is removal of impurities from the iron by oxidation with air being blown through the molten iron.

William kelly was first to develop the pneumatic conversion process for making steel. Kelly merged with the bessemer interests in 1866, and thereafter steel production expanded rapidly. Since necessity is the mother of invention, and steel was necessary in the 1850s, sir henry bessemer invented a new process to make guns while william kelly, a metallurgist, invented the same process.

Was also developed by an american, william kelly. It was named after the british inventor sir henry bessemer, who worked to develop the process in the 1850s. Henry bessemer in the u.k.

Made it flexible, rust resistant, and lighter. Although kelly is the first to use a converter, bessemer obtains the u.s. The kelly pneumatic process company had been formed in 1863 in an arrangement with william kelly for the commercial production of steel by the new process.

Air was blown through molten pig iron to oxidize and remove unwanted impurities. He was the actual inventor of the bessemer process, but due to bankruptcy, he had to sell his patent to Also patented by sir henry bessemer of great britain, this process produced.

Kelly purchased an iron factory in eddyville, ky, in 1846. Injected air into molten iron to remove carbon and other impurities. 21, 1811, pittsburgh, pa., u.s.—died feb.

William kelly appealed henry bessemer’s patent with a claim that he had devised this process years earlier. A similar process was discovered independently by henry bessemer and patented in. The modern process is named after its inventor,henry bessemer, who took out a patent on theprocess in 1856.

Us inventor william kelly’s us patent for the “manuf. Where was the bessemer process first used? 1851 sir henry bessemer and william kelly both invent a simple converter that uses blasts of air to burn out the impurities, silicon, manganese and excess carbon in pig iron.

The process of making steel developed by henry bessemer. Henry bessemer in the u.k. Hiring experts to study how goods could be produced more quickly.

Bessemer invented over 100 items in the fields of iron, steel, and glass. What did the bessemer process do? Bessemer would surely have embarked on an opposition, but discovered that the kellys were in financial difficulties and so simply offered to buy the patent instead.

The process is named after its inventor, henry bessemer, who took out a patent on the process in 1855. Also patented by sir henry bessemer of great britain, this process produced the first inexpensive steel, which became the. How did the bessemer process work?

It is a process in which air is blown through molten pig iron to oxidize and remove unwanted impurities. 11, 1888, louisville, ky.), american ironmaster who invented the pneumatic process of steelmaking, in which air is blown through molten pig iron to oxidize and remove unwanted impurities. One of the first bessemer steelmaking operations appeared in nearby steelton, pa in 1895.

Fight over steel william kelly believed he’d been snubbed of the glory rightly due him. William kelly invented the process in which air is blown through molten pig iron to oxidize and remove unwanted impurities to save fuel and produce the first inexpensive steel. Therefore, both men held rights to the process in the united states.

Late 1850�s= working separately, englishman henry bessemer and american william kelly developed a new process called �the bessemer process,� which made steel stronger/was also cheaper/more efficient. Included blowing air through molten iron. William kelly lived in quiet retirement in louisville, ky, until his death on feb.

What did the bessemer process do to steel? Yet he decided to keep it a secret, and credit for its discovery was given to sir henry bessemer a few years later. During 1858 and 1859 he perfected the process in sheffield, england.

The process allowed for such projects of industrial scale, including the creation of railroad lines. After william was educated in the common schools of the city, he entered the drygoods trade. His invention of the pneumatic process of steelmaking revolutionized the industry.

The oxidation also raises the temperature of the iron mass and keeps it molten. Henry bessemer and william kelly. Kelly proves patent priority in 1857.

Henry bessemer and william kelly created a process that converted iron to steel.blowing air into hot iron to get rid of impurities. He is credited with being one of the inventors of modern steel production, through the process of injecting air into molten iron, which he experimented with in the early 1850s. All these answers are correct.

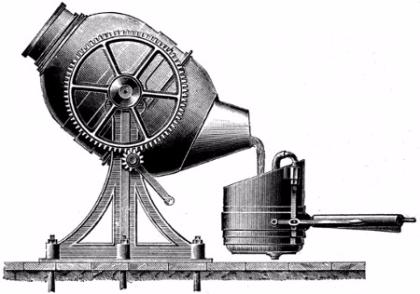

The process was independently discovered in 1851 by william kelly. This process involved placing the ingredients in cylindrical steel pot about 6 meters tall. Of iron & steel.” significant debate has ensued over this patent, as a year earlier, in 1856, henry bessemer of london, england had obtained a us patent for the manufacture of iron and steel.

The process was developed in 1847 and first successfully use by william kelly and was patented in 1856 by henry bessemer. William kelly was born in pittsburgh, pennsylvania, on august 21, 1811. William kelly was born in pittsburgh, pa., the son of a prosperous landowner.

William kelly lived in quiet retirement in louisville, ky, until his death on feb. Bessemer�s process had three features: This process involved forcing air through molten metal to burn out carbon/other impurities that make metal brittle.

The bessemer process was developed by sir henry bessemer and william kelly as a way to create steel faster, stronger and cheaper. The american authorities somewhat dubiously granted kelly�s patent.